Grouser Bar For Bulldozer and Excavator

A grouser bar is a metal component typically found on heavy machinery, such as bulldozers and track loaders. It is attached to the track shoes and helps improve traction and grip by biting into the ground. Grouser bars are essential for enhancing the machine’s performance in challenging terrain, such as loose soil or steep slopes. They come in various shapes and sizes to suit different applications and can be replaced when worn out to maintain optimal functionality.

There are several types of grouser bars available, each designed for specific applications and terrain conditions. Some common types include:

1. Single-bar grouser: This type features a single bar that provides good traction and stability on softer terrains such as mud, snow, and sand.

2. Double-bar grouser: With two parallel bars, this type offers increased traction and stability, making it suitable for more challenging terrains like rocky or uneven surfaces.

3. Triple-bar grouser: Featuring three bars, this type provides maximum traction and stability, making it ideal for demanding terrains such as steep slopes and rugged landscapes.

4. Extreme-duty grouser: These heavy-duty bars are designed for extreme conditions and heavy machinery, offering superior traction and durability.

When choosing a grouser bar, it’s important to consider the specific terrain and conditions in which it will be used to ensure optimal performance.

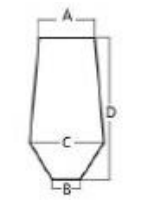

| SECTIONN | A mm | B mm | C mm | D mm | Length (mm) | W (kg) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| 610 | 7 | 5 | 22 | 40 | 610 | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | 26.987 | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | 26.987 | 12.7 | 41.275 | 82.55 | 610 | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | 610 | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | 610 | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | 711 | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | 610 | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | 610 | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25″ | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25″ | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25″ | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

Material : 65Mn Hardness : HB300~HB320 Length customizable, max 6000mm

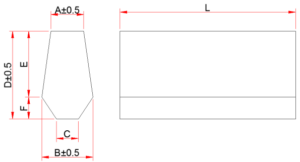

| Part number | A | B | C | D | E | F | L | W (KG) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0.4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Material : 40Cr Hardness : HB500 Casting and Heat treatment needed.

| Part number | A | B | C | D | E | F | L | W (KG) |

| ECORK 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| GCORK 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| JCORK 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| ACORK 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| WCORK 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KCORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| CCORK 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Material : 42CrMoNi Hardness : HB500-550 Casting and Heat treatment needed.

| Part number | A | B | C | D | E | F | L | W (KG) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | 610 | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | 610 | 10.4 |