Categories

The tips of choosing the suitable excavator track shoes for us

The excavator is one of the mini excavator parts, as a mini excavator parts China manufacturer we are glad to introduce some tips to you when you choose these mini excavator parts may need. Before we know how to choose the excavator track shoes, we need to figure out what is track shoe excavator. The introduction of the excavator track shoes The excavator track shoes are one of the components of...

GT team in Dubai ! الفريق في دبي

Dubai is one of the seven emirates that make up the United Arab Emirates (UAE), situated on the southeastern coast of the ArabianPeninsula. It is known for its stunning modern architecture, luxury shopping, vibrant nightlife, and thriving business environment. Travel gives people the opportunity to experience first-hand the culture, history, customs and lifestyles of different countries […]

The importance and future development of XMGT excavator

The operation of XMGT excavators pin plays a crucial role to power transmission. It's also a bridge for the collaborative work of various components. This article will delve into the importance of sales shafts for the excavator industry and the development prospects of this field. The Key Role of Pins in Excavators The power transmission of excavators relies on rotating bearings, which are a...

Welcome to watch GT Brazil Exhibition

Dear Sir/Madam, We sincerely invite you to visit M&T EXPO GT to communicate and visit our booth E61-8. This exhibition is a great opportunity for you to gain an in-depth understanding of the latest machinery and equipment technology and network with industry leaders. Date: April 23-April 26 Location: Sao Paulo, Brazil At our booth E61-8 you will have the opportunity to: Learn about our...

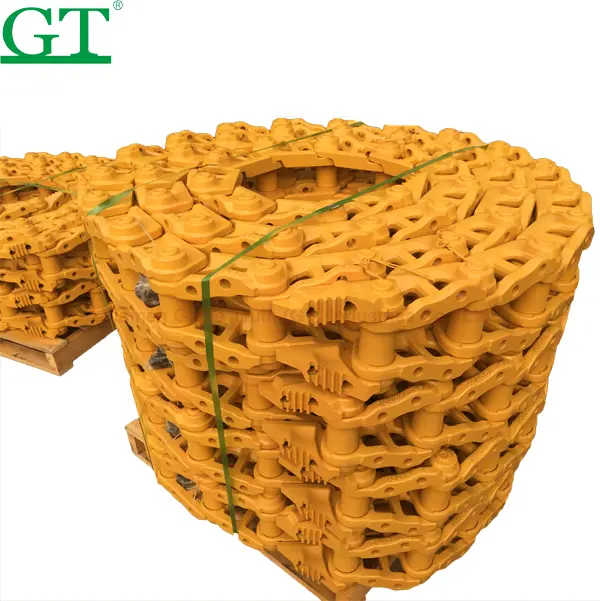

What are the parts of an undercarriage

If you have worked in the industrial which can contact the excavator, you certainly know some about the parts of undercarriage. Because the undercarriage is a crucial part of the excavator. Usually, the undercarriage has five parts, they are the excavator track roller, excavator driving wheel, excavator guide wheel, excavator supporting sprocket and excavator track. If you ask which part is the...

Redefining Efficiency With Top-notch Mini Excavator Undercarriage Parts

In the world of construction, efficiency and reliability are key. For those in the know, XMGT, a leading mini excavator parts China manufacturer, has become synonymous with these qualities. With a focus on producing high-quality mini excavator undercarriage parts, XMGT is making waves in the construction industry, both domestically and internationally. XMGT: A Beacon of Quality XMGT...

Stand E61-8 de M&T Expo-GT

Estimados clientes, Nos complace anunciar que estaremos presentes en la próxima M&T Expo, que tendrá lugar del 23 al 26 de abril de 2024. Les invitamos cordialmente a visitarnos en nuestro stand E61-8, donde estaremos encantados de mostrarles nuestros últimos productos y soluciones. Será una excelente oportunidad para conversar personalmente y discutir cómo podemos apoyar sus necesidades de...

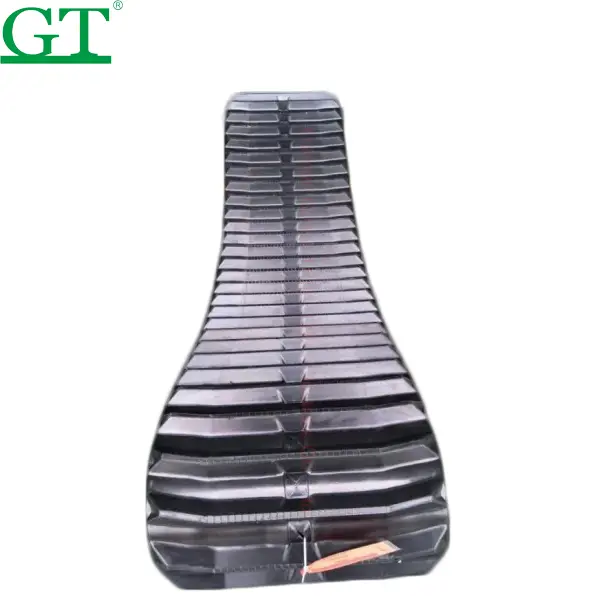

Instructions For Use of Rubber Tracks

A. Right track tension Keep the correct tension on your tracks at all times Check the tension at the center track roller(H=1 0-20mm) Avoid track under tensioned The track can come off easily. causing inside rubber scratched and damaged by sprocket, or broken when the track engages undercarriage parts not correctly,or hard objects get into between sprocket or idler assay and...

The Role Of XMGT Excavator Tracks And Tensioners In Construction

In the heavy machinery industry, excavators play a core role with their precise and efficient operational capabilities. The core role of excavators in these industries highlights their indispensable role in heavy machinery applications, and their consistent reliability under various conditions sets a benchmark for efficient operation. Among its many complex components, track chains and...

GT Forging Idler for sale

Excavator forging idlers are crucial components of an excavator's undercarriage system. To prolong the life of an excavator forging idler, it is important to follow some maintenance tips and best practices: Keep the idler clean from dirt, debris, and mud to prevent premature wear. Regularly inspect the idler for any signs of damage or wear, such as cracks or worn-out edges. Ensure proper...