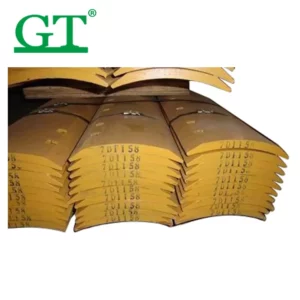

Ripper Shank

GT Industries has been a trusted provider of high-quality undercarriage and work tool components to construction equipment customers for over 20 years. With a specialization in Ripper Shanks, our products are engineered to ensure maximum durability in demanding worksites. As a reputable manufacturer and supplier of Ripper Shanks in China, GT Industries offers top-notch quality at competitive factory wholesale prices. If you're looking for reliable and durable Ripper Shanks, please contact us for a competitive inquiry. We are ready to meet your needs.

A ripper shank is a heavy duty hardened cutting edge/tooth that is attached to the end of a multi-shank ripper assembly on an excavator.

Ripper Shank Materials From GT:

- Common materials of ripper shank should be below:

- Heavy duty high-carbon alloy steels for strength and hardness

- Carbide-tipped versions with tungsten carbide or other hard metal inserts

- Titanium alloys for corrosion resistance in poor soil conditions

Applications Of GT Ripper Shank:

- Ripping/breaking up dense hard soil, compacted materials, asphalt, bedrock

- Demolition of old foundations, pavement and slabs

- Land clearing and grubbing to remove stumps/roots

Benefits Of Ripper Shanks:

- Deeply fracture and break up compacted/hard surfaces better than a standard bucket

- Allow excavators to rip and remove materials a standard bucket can’t

- Increase productivity for demolition or land clearing work

- Options with carbide teeth last much longer than steel for abrasive conditions

- Corrosion-resistant materials like titanium prevent premature wear